Audio Shielded Cable

Audio Shielded Cable is another product that people with various features may be dealing with. This type of shield cable can be one of the most important applications in the field of production of highly efficient and naturally used electrical equipment. To get more familiar with these types of cables you need to study the features and how they work.

A summary of what we are going to explain in this article is why audio shields are one of the most important elements needed to prevent unwanted sound from being released into your sound system. But with the different types of audio shield cables, choosing between them can seem daunting. Here are three main types of audio shield cables.

The main function

The basic task of the audio shielded cable is simple and simple: transmit the audio signal from one point to another. However, another reason we want to use audio cables is that they are expected to retain any unwanted (so-called noise) noise from entering that main audio signal. And when determining the best type of cable to suit your needs, the amount of unwanted noise reduction will be extremely important.

Audio Shielded Cable

Unwanted noise typically enters the audio signal path via radio frequency interference (RFI) or electromagnetic interference (EMI) along the cable. Naturally, the longer the cable, the more likely it is that the interference will join the original audio signal and produce itself in the output source as sound, vibration, static or other unwanted sounds. Shielded audio cables are used to prevent RFI and EMI.

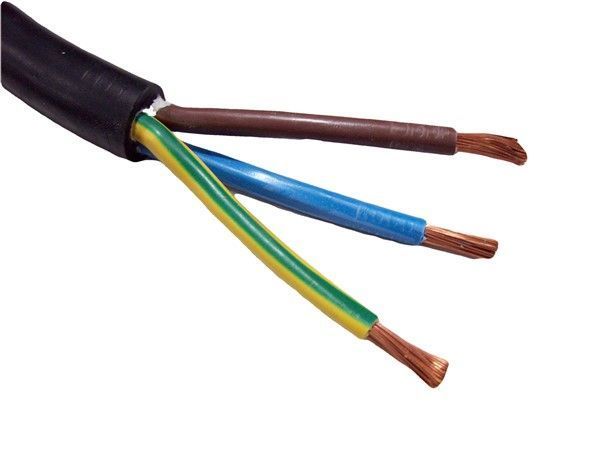

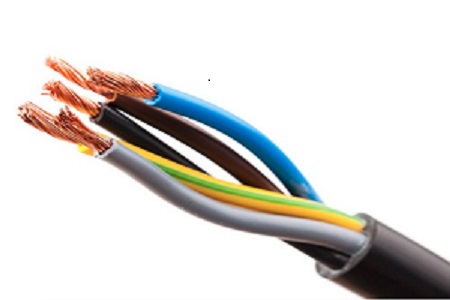

The audio shielded cable literally protects the main wires (conductors) that transmit the original audio sound from external interference. Shielded cables are usually made of copper wire strands. It also performs the function of grounding the audio signals. There are several types of shielded cables that you need to know before deciding what you are going to use.

Woven Shielded Cables

As its name implies, a shielded acoustic shielded cable protects the original signal transducer by covering the main conductor with the surrounding braided copper strands. The benefits of using woven shields include the fact that the coverage area that the shield can protect depends on the thickness of the coating, the amount of blows (from outside) and the amount of use it can make, the area covered by the wire being protected. . Therefore, the coverage can range from less than 50% to nearly 97%. In addition, this type of coating is very suitable. They are therefore particularly effective in preventing interference from RFI sources, which have very short wavelengths that can sometimes block other types of shields.

The two main barriers to using woven shields are cost and flexibility. Knitting copper strands together requires machines that work at relatively low speeds due to the complexity of the work process, resulting in higher production costs. In addition, the higher the complexity of the woven shields (copper coating on the main conductor), which has a direct effect on reducing unwanted noise, ultimately leading to less cable flexibility, which is more susceptible to twisting in the cable. Be it.

For this reason, “Shielded” cables are usually used for permanent installations and studio use where the cable is not subject to the twists and turns that often occur during everyday use. A wide range of microphone and guitar cables are fitted with this type of audio shielded cable.

Service Shielded Cables

A service acoustic shield cable is made like a woven shield, except that a flat layer made of copper strands is positioned around a main signal conductor in one direction. Shield cables are more flexible than woven shields and are generally better suited for everyday living.

Consider the needs of a live guitarist. Part of his performance is walking and climbing the stage, jumping off the speaker drum and throwing his guitar in the air. Since these activities (even some of the more adventurous activities) can easily have a twist and shake in cable, the flexibility of service providers means that such twists in cable are far less likely. They damage the shield, resulting in a longer cable life.

The disadvantage of a service shielded audio cable is that they will not shield as much as the shields, especially RFIs, and although they are longer than the shields in ambient conditions, their shielding capability will be weakened over the life of the cable. Be.

Shielded service cables are also less expensive than woven shields because they are much shorter in production process and use less copper.

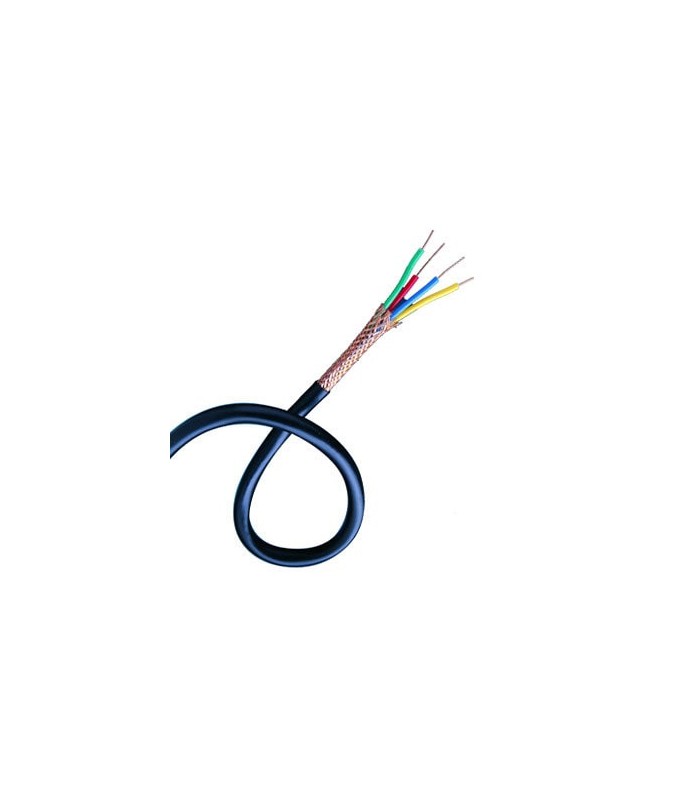

Foil Shielded Cables

Foil acoustic shielded cable provides maximum protection (100%) in coverage. The coating is formed by placing a thin layer of mylar (a type of polyester) next to an aluminum foil covered with copper water. This metal-to-metal contact (produced using short circuits) increases the foil’s effectiveness range to include higher frequencies. While the foil shield cables are lightweight and inexpensive, the copper layer impedes flexibility and, if repeatedly bent, the coating breaks down rapidly. Foil shields are generally used in multicore and digital audio cables.

Protection is one of the most important aspects to consider when building an audio system. And like most products in the audio world, the best type of shield or shield for you depends entirely on your specific needs. But ultimately, most people need a service shield to meet the needs of day-to-day projects or live performance, while a woven acoustic cable or foil may be required for cables that remain in a home or studio. Be better.